Vertically integrated, full-service electronics manufacturing solutions

Vertical Business

©2024 SVI Public Company Limited.

All rights reserved.

Vertical Business

As global markets continue to evolve due to fast-paced digital innovation, OEMs face increasing pressures to deliver high-quality products efficiently and cost-effectively while maintaining profitability and market share.

Yet, given rising global inflation rates, 9 out of 10 manufacturers are experiencing rising costs, which is exacerbating the pressure to deliver beyond fluctuating market demand.

The challenge is compounded by the complexities of modern supply chains, where dependencies on multiple suppliers can lead to vulnerabilities, inefficiencies, and increased costs, in addition to external disruptors. Only 6% of businesses have achieved full supply chain visibility in this supply chain landscape.

The quest for more streamlined, resilient, and competitive manufacturing processes, complete with predictable supply chains and more accurate financial planning, has led many OEMs to consider the strategic advantages of a vertical integration solution.

This business strategy involves the centralized control of multiple production stages, typically handled by several separate entities, within the purview of a single service provider. Consolidating the production lifecycle and value chain in this way reduces costs, enhances product quality, improves supply chain coordination, and increases market responsiveness.

Mark Whittaker – General Manager, Thomson FM

Partnering with a vertically integrated contract manufacturer reduces OEM reliance on multiple external suppliers, lowers the probability of supply chain disruptions, and provides greater control over production costs and quality. Additionally, it facilitates closer collaboration between the different phases of product design and manufacturing, accelerating innovation and streamlining the path from product conception to market delivery. In industries where speed and reliability are paramount, vertical integration can provide a significant competitive edge.

In simple terms, vertical integration is an operational strategy in which a company streamlines its operations by taking direct ownership of various stages of its production process rather than relying on external contractors or suppliers.

This approach allows for greater control over the supply chain, bringing several benefits while mitigating specific challenges and risks.

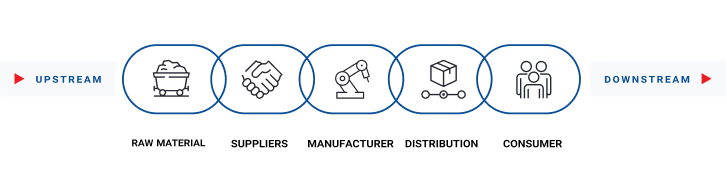

In the context of EMS, it involves a contract manufacturing company expanding its operations into various areas along the value chain to include different points on the same production path. This can include everything from sourcing raw materials to final product assembly and distribution.

For example, a vertically integrated EMS provider might carry out Design for Excellence (DfX), source necessary materials, manufacture critical electronic components, assemble PCBs, and manage final product assembly and distribution from their own centralized facilities. This model is diametrically opposed to the "best of breed" approach, where an OEM might use different suppliers for each individual phase of production, which can complicate coordination and communication, increase overhead costs and lead times, introduce greater risk in the supply chain and result in a fragmented production process.

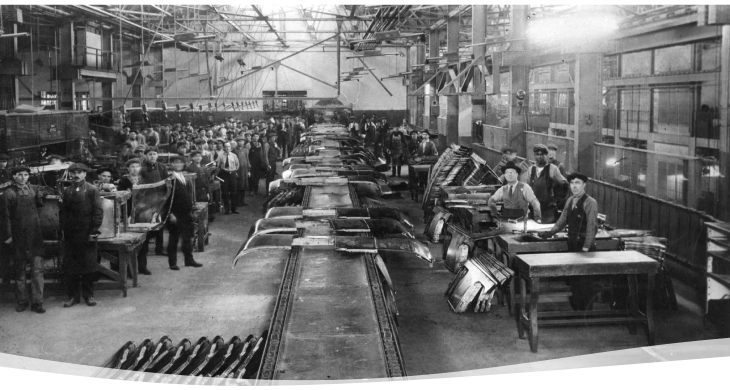

The concept of vertical integration is not new, but it has historically been a game changer within the manufacturing industry. Pioneered by industry titans like Henry Ford and Andrew Carnegie, it was instrumental in their dominating the automobile and steel industries, respectively, in the early 20th century.

Ford, for example, expanded his company’s production capabilities —and therefore the Ford empire—by purchasing a railroad, acquiring control of 16 coal mines and about 700,000 acres of timberland, building a sawmill, acquiring a fleet of Great Lakes freighters to transport ore from his Lake Superior mines, and even buying a glassworks, all in aid of streamlining the production of Ford automobiles. This integrated approach drastically reduced production costs and improved process efficiency–principles still highly relevant in today's EMS landscape.

Mark Whittaker – General Manager, Thomson FM

Forward vertical integration encompasses all the downstream activities in the supply chain, such as distribution, sales, and sometimes even customer service, that come after a finished product has been manufactured. Backward vertical integration, on the other hand, encompasses those supply chain activities further upstream that typically involve the production or sourcing of raw materials or critical components necessary for manufacturing operations to be carried out in the first place.

Forward vertical integration typically sees an EMS provider managing how products are packaged and delivered, ensuring that the end user receives consistent quality and service. An EMS company might establish its own logistics branches to handle product distribution, reducing dependency on third-party logistics services and improving delivery timelines for OEM customers. The EMS provider would also likely provide aftermarket services, such as repair or rework for customers' products in circulation.

Similarly, a backward vertically integrated EMS provider entails the contract manufacturer securing its supply of critical inputs, reducing production costs, and increasing control over pre-production factors like the quality of the materials used in its manufacturing processes and the efficiency of associated procurement processes. They would also have maximum oversight and control of NPI, DfX, and design and development processes, ensuring complete alignment with post-production processes. Backward vertical integration is particularly significant for tightly regulated markets, such as Medical Technology, where component quality directly impacts the final product's performance and reliability.

Forward and backward vertical integration strategies enable EMS providers to enhance operational control, increase market responsiveness, and provide OEM clients with a more cohesive product and service offering across the value chain. This, in turn, streamlines production and distribution processes for OEMs, reducing their reliance on multiple external entities while improving their ability to quickly meet customer needs, leading to a fortified market position.

Leveraging vertical integration, EMS providers can offer a comprehensive suite of services that ensure continuity and efficiency, from initial design to aftermarket services.

Each stage of a vertically integrated service offering is designed to dovetail seamlessly into the next, ensuring the entire production process is smooth and efficient, creating a predictable time-to-market and reliable finished product.

EMS services that can benefit include:

NPI and product prototyping greatly benefit from a vertically integrated approach, which supports the seamless transition between design, testing, and mass production phases. It enables a streamlined workflow where feedback from the prototyping phase can quickly be incorporated into design adjustments, significantly reducing the development cycle and enhancing EMS providers’ ability to innovate rapidly. Having the design and prototyping teams in close proximity to each other facilitates a more iterative process that can adapt swiftly to new innovations or market/industry changes, improving the overall quality and effectiveness of the final product.

Vertical integration in design and development processes provides the advantage of close collaboration between cross-functional teams, including engineering, manufacturing, and quality assurance. This integration fosters a holistic approach to product development, where designs are optimized for procurement, reliability, performance, testing, manufacturability, quality and sustainment. With immediate access to production capabilities and real-time manufacturing feedback, design engineers can adapt designs to meet practical production constraints, resulting in more feasible products produced more quickly.

With an EMS partner who offers test development under their in-house service offering, the test development phase is directly linked to the manufacturing phase, allowing test engineers to develop specific testing protocols that are finely tuned to the products being manufactured. This ensures that testing equipment and procedures align perfectly with the production specifications and processes, leading to higher product reliability and consistency while reducing the risks associated with transferring the product to an external third-party tester before commencing manufacturing. Moreover, any issues identified during testing can be quickly relayed back to the design and manufacturing teams for rapid corrections, enhancing overall product quality while saving time.

Vertical integration in manufacturing processes like PCB assembly, box build assembly, and custom manufacturing allows for tighter control over the entire production line. This control results in consistent quality and reduced lead times, as the entire process, from sourcing raw materials to final assembly, is under one governance system. Additionally, vertically integrated manufacturing processes can adapt more quickly to changes in product design or customer demand, providing a competitive edge in responsiveness and flexibility.

A vertically integrated EMS provider has integrated control over every stage of the production process, allowing for uniform quality standards and procedures across all phases of manufacturing, from initial component fabrication to final assembly. This centralized oversight ensures that any deviations from quality standards are quickly identified and addressed, reducing the risk of defects and ensuring that the final products consistently meet and exceed customer expectations.

Global supply chain management under a vertically integrated model allows for better coordination and efficiency across the supply chain. With control over both supply and distribution channels, an EMS partner can optimize inventory levels, reduce transportation costs, and minimize delays caused by external dependencies. This cohesive control over the supply chain not only improves operational efficiency for OEMs but also enhances their ability to react swiftly to market changes or disruptions.

Digitally transformed EMS providers leverage centralized systems, data, and processes to enhance operational efficiency and product innovation. Vertical integration then facilitates the seamless flow of information across different stages of production, enabling the use of advanced analytics, machine learning, and IoT technologies to optimize manufacturing processes. This technology-driven approach improves production capabilities and supports proactive maintenance, quality control, and overall supply chain management.

Integrating third-party logistics fulfilment and distribution with an EMS provider's overall offering enhances control over the end-to-end product journey from manufacturing to customer delivery. This control can lead to optimized routing, better inventory management, and reduced logistics costs. Moreover, having an integrated logistics system allows for more flexible and responsive customer service, including faster delivery times and more reliable order fulfillment–especially if the vertically integrated manufacturing partner has a regional presence in close proximity to end customers.

Aftermarket services benefit from having direct access to product design and manufacturing data, which aids in maintenance, repairs, and reverse logistics efforts. This integration enables service providers to offer more accurate diagnostics, faster service, and tailored support, improving OEMs' end-customer satisfaction and loyalty. Additionally, insights gained from aftermarket services can be fed back into the design and manufacturing processes to enhance product quality and reliability further.

Considering the integrated nature of end-to-end manufacturing services, vertical integration offers tangible benefits across an EMS business' offering.

Managing fewer suppliers and points of contact simplifies logistics and strengthens relations between OEMs and fewer, more strategic partners. These enhanced relationships foster better communication and collaboration, which can lead to innovations and improvements in processes and products. Additionally, a simplified supply chain is typically more transparent, making monitoring for compliance and ethical standards easier.

Reduced production, transaction and transportation costs: With vertical integration, EMS partners can offer economies of scale that enable more efficient resource allocation across the production cycle. This efficiency helps OEMs reduce margin stacking associated with managing multiple contracts and negotiating with various suppliers, which can further translate into more competitive pricing. It also streamlines the transportation of goods, reducing logistical costs by minimizing the distances materials and products need to travel.

With vertical integration, EMS partners can offer economies of scale that enable more efficient resource allocation across the production cycle. This efficiency helps OEMs reduce margin stacking associated with managing multiple contracts and negotiating with various suppliers, which can further translate into more competitive pricing. It also streamlines the transportation of goods, reducing logistical costs by minimizing the distances materials and products need to travel.

An integrated approach allows stricter quality control measures to be implemented and monitored throughout every production process. This control leads to consistent product standards and reduces the variability in products sourced from multiple suppliers. Consequently, this can significantly lower the rate of returns and increase customer trust and satisfaction, fostering stronger brand loyalty.

Sales, Inventory, and Operations Planning (SIOP) benefit greatly from the coherent and synchronized flow of information that vertical integration provides. This integration ensures that companies' sales forecasts, production planning, and inventory management are closely aligned, which minimizes stock-outs and overstock situations. Improved forecasting accuracy also allows for better financial planning and investment in product innovation and digital transformation.

EMS providers can push products from concept to market much faster by eliminating delays associated with coordinating multiple suppliers. This speed to market is a critical competitive advantage, particularly in industries where products rapidly evolve. Faster product launches can satisfy market demand more promptly and capitalize on market trends ahead of competitors.

With the support of a vertically integrated EMS partner, OEMs can address customer needs more promptly throughout the production cycle. This includes quickly adapting products to changing expectations, enhancing customization capabilities to meet specific customer demands, and streamlining delivery through single distribution channels. Moreover, due to EMS’ integrated oversight of the entire production process, any issues can be resolved swiftly, often before they reach the customer.

An OEM that employs a contract manufacturing partner using vertical integration often enjoys a protected market position because competitors struggle to replicate such a comprehensive setup. This security stems from end-to-end control over technologies and processes and building a reputation for reliability and customer-centricity.

Vertically integrated contract manufacturing gives OEMs greater control over their inputs and outputs, reducing exposure to external risks such as third-party supplier failures, sudden price hikes in raw materials, or geopolitical tensions that may affect the supply chain. This integrated control enables them to respond more flexibly and resiliently to market changes, maintaining stability and continuity in operations.

With a vertically integrated manufacturing partner, companies can more effectively customize products to meet specific customer demands, integrating feedback directly into the product development cycle. This responsiveness leads to innovative products that closely match market needs, creating distinctive product offerings that set OEMs apart from competitors. Enhanced capacity for rapid iteration and refinement further fuels product innovation.

Adopting advanced technologies such as AI and IoT across multiple stages of production and management leads to smarter, more automated operations. This transformation allows for real-time data collection and analysis, optimizing everything from inventory management to quality control and predictive maintenance. Such integrated digital ecosystems not only reduce labor costs but also enhance precision and efficiency in production, leading to significant savings and improved outputs.

Partnering with vertically integrated suppliers can be a strategic move for OEMs, particularly when facing challenges with production scalability, market expansion, or supply chain reliability.

In these cases, it may prove not just beneficial but essential. Here's when to consider it:

OEMs needing to scale up their production capabilities to meet growing market demands may find vertical integration a viable strategy, especially for industries where the volume and complexity of products can increase rapidly, such as consumer electronics or electric vehicles. An integrated end-to-end supplier gives OEMs greater control over their production capacities, adjusting them quickly and efficiently without being constrained by multiple external suppliers' limitations or delays.

Similarly, when entering new geographical or product markets, vertical integration can help OEMs mitigate risks associated with unfamiliar local supply chains or regulatory environments. EMS partners with control over the entire value chain across regions and markets allow OEMs to better adapt to local market requirements and regulations, setting them up for international success from the start.

OEMs cannot afford delays or quality issues caused by supplier inconsistencies, especially when, according to Supply Chain Drive, the average cost of a supply chain disruption is $1.5 million per day. Vertically integrated manufacturers maintain stringent control over the entire supply chain, ensuring that every component meets OEMs' exact specifications and requirements, from initial concept design to final product delivery.

Having a dependable buffer in environments where external factors, such as political instability, trade conflicts, or pandemics, can disrupt supply chains can prove invaluable. In 2022, 82% of supply chain leaders experienced at least one significant supply chain disruption, and 50% experienced three or more due to the conflicts in Europe and the ripple effect of COVID-19. By relying on a single provider with more control of the supply chain, companies reduce their vulnerability to external disruptions, maintaining production and supply consistency.

Certain markets benefit more distinctly from vertical integration due to their specific requirements. These include:

Medical Technology & Devices |

In the MedTech market, where stringent quality controls and traceability are critical for ensuring final product quality and functionality adhere to strict regulatory protocols, vertical integration can help OEMs stay compliant.

Automotive, E-mobility & Transport |

In this market that requires the integration of advanced technologies and high reliability at greater speed and scale than other markets, vertical integration can be particularly advantageous.

Advanced Communication |

This sector, characterized by rapid prototyping and scalability for emerging technologies, greatly benefits from vertical integration.

Audio Video & Security |

OEMs can carve out a distinct competitive advantage in the Audio Video and Security market where vertical integration can speed up innovation and product delivery.

Aerospace |

The Aerospace market can benefit from vertical integration to meet its high standards for precision and reliability. Integrated manufacturers can control the entire production process, from component fabrication to final assembly.

Industrial Automation |

In Industrial Automation, a vertical integration strategy sees a supplier streamline system development and implementation, ensuring custom-fit solutions and rapid adaptation to technological advancements for clients.

Clean Energy Systems |

OEMs in clean energy, like solar and wind, enhance their control over high-tech component production and adaptability through vertically integrated supply partners, which is vital for quality, efficiency, and keeping pace with technological and regulatory changes.

Consumer Electronics |

Vertically integrated EMS partners help OEMs keep pace with rapid product life cycles and evolving consumer expectations. Control over the entire value chain, from chip manufacturing to final assembly, allows for quicker responses to market trends and technology changes and better cost management.

When selecting an EMS partner, OEMs should consider several key factors to ensure that the partnership will meet their strategic goals and operational requirements, such as:

Capability and expertise: Assess the scope of the potential partner's service offering to ensure they can handle all stages of the product lifecycle, from design and prototyping to manufacturing and aftermarket support. Evaluate the technical and engineering expertise available, especially for specialized product requirements.

Quality and compliance standards: Verify that the partner adheres to relevant industry standards and certifications, ensuring compliance with quality, safety, and regulatory requirements. Also, look for robust quality assurance processes that align with your expectations and industry requirements.

Scalability and flexibility: Consider whether the partner can scale operations up or down based on market conditions and your company's growth trajectory. Check how flexibly they can handle varying production volumes and their ability to adapt to changing product specifications or market needs.

Supply chain robustness: Analyze the resilience and transparency of the partner's supply chain. A vertically integrated supplier should provide greater control and visibility over the supply chain, minimizing risks associated with supply disruptions.

Innovation and technological advancement: Determine the partner's commitment to innovation and ability to integrate the latest technologies into their processes. Look for a partner with advanced, high-tech capabilities to keep your production processes ahead of the curve.

Cultural and strategic alignment: Partnerships should be built on a sound understanding of your business goals, work culture, and strategic objectives. Evaluate the potential partner's corporate culture and governance structures to ensure compatibility with your own business ethos.

The strategic use of vertical integration in the EMS sector aligns all stages of production under a single operational umbrella, enhancing control and efficiency across the entire product lifecycle and value chain. This model significantly reduces complexity in the supply chain, diminishes production and transaction costs, and elevates the overall quality and reliability of products.

For OEMs in certain markets with particular strategic imperatives, leveraging the capabilities of a vertically integrated EMS partner also fortifies their ability to innovate and respond rapidly to market changes. This is crucial in industries characterized by rapid technological advancements and shifting consumer demands amid growing competition and supply chain complexity.

In such a landscape, an EMS partner with vertically integrated capabilities across a comprehensive suite of services provides the robust capability to manage complex manufacturing processes efficiently and effectively. This simplifies logistics, reduces the risks associated with multiple suppliers and streamlines the entire production process, ensuring that products are delivered on time and to the highest standards.

By choosing an integrated contract manufacturing partner, OEMs also gain access to an industry leader in operational efficiency and technological advancement. This makes their choice of EMS provider crucial, as the right partner can be a powerful ally for OEMs looking to optimize their production capabilities and achieve sustainable growth in today's challenging and dynamic market environment.

Contact our team of experts to learn more about SVI's vertical integration capabilities and how we can support your goals.

By submitting this form, you agree to our Privacy Policy.

141-142, Bangkadi Industrial Alley,

Bangkadi, Mueang Pathum Thani

District, Pathum Thani 12000,

Thailand

By submitting this form, you agree to our Privacy Policy.

141-142 Moo 5,

Tiwanon Road, Bangkadi,

Pathumthani 12000, Thailand

© SVI Public Company Limited. All rights reserved.