In-House Vs Specialist Vs EMS Electronic Product Design and Development

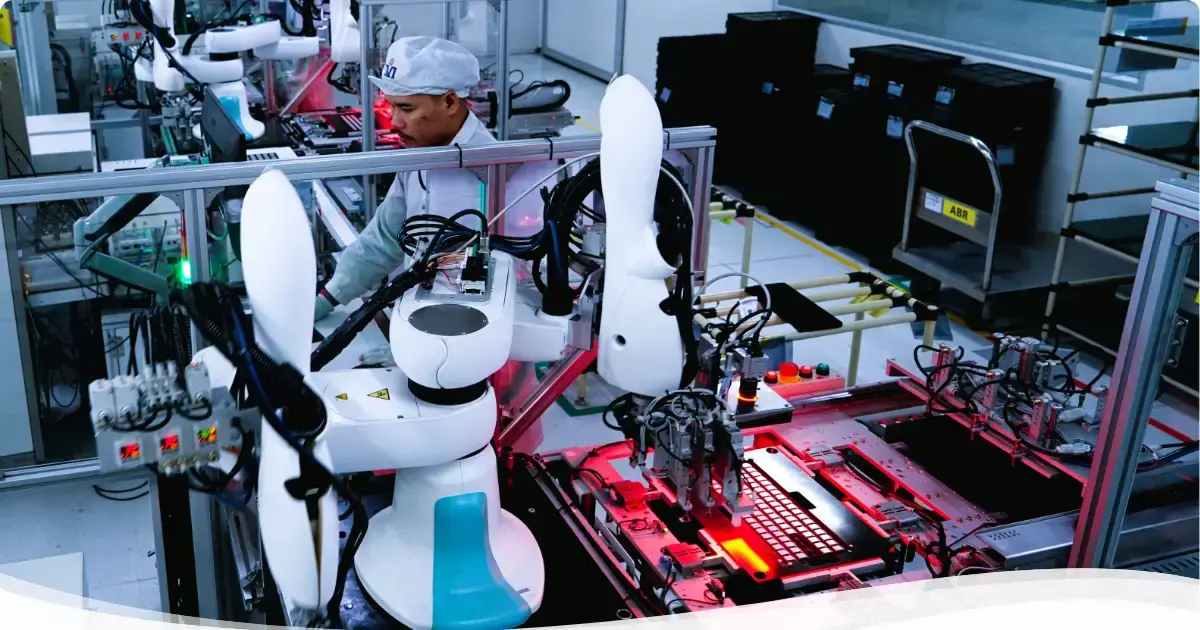

Electronics manufacturing is a fast-paced industry that demands quick innovation and delivery. Amid this pressure, companies face the crucial decision of how to best handle their electronic product design and development in a way that aligns with their business goals and market demands. The choice of whether to keep these processes in-house, collaborate with specialist design and prototyping houses, or partner with a full-service EMS provider can significantly influence an OEM’s innovation capabilities, operational efficiency, and market competitiveness.

Each option offers distinct advantages and challenges, shaping not only the final product but also the company's strategic trajectory in the high-stakes tech industry. Whether you're looking to control every detail of design, leverage cutting-edge expertise, or enjoy the efficiencies of a vertically integrated provider, understanding the pros and cons of these options is a critical step in optimizing your product's journey from concept to consumer.

In-house electronic design and development

In-house electronic design and development allows an OEM to control its product design processes completely, ensuring all facets of the design and development are specifically tailored to the company's needs without the risks associated with external partnerships. This approach enables internal teams to integrate seamlessly, ensuring that every product development phase aligns with the company's overall strategic objectives and values.

Moreover, it provides an added layer of security for intellectual property if concealing proprietary knowledge and design work is vital to an OEM's strategy. This control and integration fosters a strong sense of ownership and alignment with the company's long-term goals from within the organization.

Potential drawbacks to keep in mind

Despite this increased control, keeping your electronic design and development in-house does come with significant financial implications. The upfront costs of setting up and maintaining state-of-the-art equipment and technology can be substantial. As technology evolves, continuous investment in training and skills development also becomes necessary to keep your design team on the cutting edge, further increasing overhead costs.

Another critical drawback is scalability. In-house operations may struggle to scale up efficiently in response to increasing market demand or to pivot quickly in the face of changing industry trends, potentially limiting your ability to respond agilely to new opportunities.

Specialist design houses

Specialist design and prototyping houses offer a distinct advantage by bringing a high level of expertise and specialized knowledge to electronic product design and development. These entities focus solely on the design and early development stages of product creation, allowing them to continuously refine their specialized offering in accordance with the latest tech advancements and best practices.

This specialization often results in more innovative solutions and rapid prototype development, which is crucial for companies looking to test and refine their concepts quickly. Additionally, the agility of these specialists allows for rapid adaptation to new trends and technologies, which can be a significant advantage in fast-moving sectors.

Risks associated with specialist design houses

However, this expertise comes at a cost. Specialist design houses typically charge a premium for their services, reflecting the advanced skills and technologies they provide. This can make budgeting for projects particularly challenging, especially for startups or smaller manufacturers with limited financial resources.

Another downside is the potential disconnect between the specialists' design phase and subsequent manufacturing phases, which are either kept in-house or taken to a third-party manufacturer. This separation can lead to potentially disastrous misalignment and complications if the designs are not fully compatible with production capabilities or if modifications are required further down the production line.

In this sense, relying on external specialists for critical phases of product development introduces considerable risk. Communication breakdowns, differences in project vision and delays in deliverables can all impact the final product's quality and time to market, not to mention the overall budget forecasts.

Therefore, while specialist design houses can offer significant advantages in terms of innovation and speed, companies must carefully manage these relationships to ensure seamless integration of the designs into their production processes and overall business strategy.

Full-service EMS providers

Full-service Electronics Manufacturing Service providers offer a comprehensive solution that spans initial design and prototyping through to final manufacturing and post-manufacturing support. This holistic approach is particularly beneficial for OEMs looking to streamline their operations, as it allows for significant efficiencies in both time and cost.

Companies can also leverage the EMS provider's scalability and vertically integrated capabilities by consolidating various phases of the product development cycle under a single provider. This not only simplifies the supply chain but also enhances cost-effectiveness, especially at larger scales.

Additionally, full-service EMS providers often have established global supply chains, logistics networks, and a global presence across strategic markets to support nearshoring manufacturing, enabling them to support various customer needs across different geographies.

Cons of working with an EMS provider for electronic product design and development

One potential downside to working with full-service EMS providers is the possible reduction in control over specific design details. An EMS might have standardized design processes, limiting how customizable a product design can be. This would concern OEMs requiring highly specialized or innovative product features.

Furthermore, EMS providers' expertise can vary significantly depending on industry or product type, which means that not all providers may be well-suited to every market or project's specific technical requirements. It's important to assess an EMS provider's market experience and track record to properly assess its industry expertise and ensure it aligns with your industry-specific needs.

Another consideration is the initial complexity and time involved in partnering with a full-service EMS provider. The beginning phase of integrating systems and aligning strategic objectives can be time-consuming and require substantial upfront investment in time and coordination. Still, the EMS should have the know-how to streamline onboarding and thus reduce integration and alignment headaches.

Despite these challenges, for many companies, the long-term benefits of reduced operational complexity, improved scalability, enhanced supply chain efficiency, and access to global markets make partnering with a full-service EMS provider a strategic and profitable decision.

Which electronic design and development route is best for you?

Designing and developing your electronic product is an essential prerequisite for full-scale manufacturing, and it needs to be done right to ensure a smooth production process from beginning to end.

Each of the three models—in-house, specialist design houses, and full-service EMS providers—offers unique advantages and comes with its own challenges. In-house development provides maximum control and security over intellectual properties but requires significant investment and can struggle with scalability.

Specialist design and prototyping houses offer cutting-edge expertise and flexibility. However, they may be more expensive and can lead to integration and alignment challenges with later manufacturing phases, which can have a devastating knock-on effect on the value chain.

Full-service EMS providers, on the other hand, deliver a streamlined, cost-effective solution from design to delivery, but this might come at the cost of reduced control over the design process and a complex setup phase.

Defining your company's version of success and its "essentials" and "nice to haves" is key to guiding your decision and ensuring you pick the right electronic design and development solution for your needs.

.webp?width=800&height=922&name=In-house%20Specialist%20design%20house%20(4).webp)

Conclusion

Choosing the right electronic product design and development approach is crucial for any company looking to maintain its competitive edge and fast-track time to market. Both in-house, specialist design houses, and EMS partner routes have their respective benefits and drawbacks to weigh up when assessing the best approach for your company.

When considering your options, your decision should align with your company's strategic goals, budget constraints, and market demands. It's also critical to consider the specific needs of your product and industry. If innovation and control are a priority, you might lean towards in-house or specialist solutions. At the same time, if you value efficiency and scalability, you might find full-service EMS providers the optimal choice.

SVI’s electronic product design and development expertise

Engaging with a seasoned EMS partner with a global presence and cross-market experience, like SVI, can provide deeper insights into how integrated solutions can streamline your product development lifecycle and accelerate your time to market.

Providing the best of both worlds, an EMS partner like us can provide the expertise and flexibility to design and develop innovative electronic products while supporting the entire product lifecycle for maximum efficiency and scalability. Our vertically integrated approach and global supply chain capabilities help OEMs deliver cutting-edge solutions to market quickly, cost-effectively and to specification at every point in the value chain.

Learn more about our NPI and Design and Development services, or contact our team to discover how we can help you achieve manufacturing excellence.

Supanee Nookaew

Supanee Nookaew

.png?width=318&height=201&name=mm-ebook%20(1).png)