Benefits of Test Design & Development Services from an EMS Partner

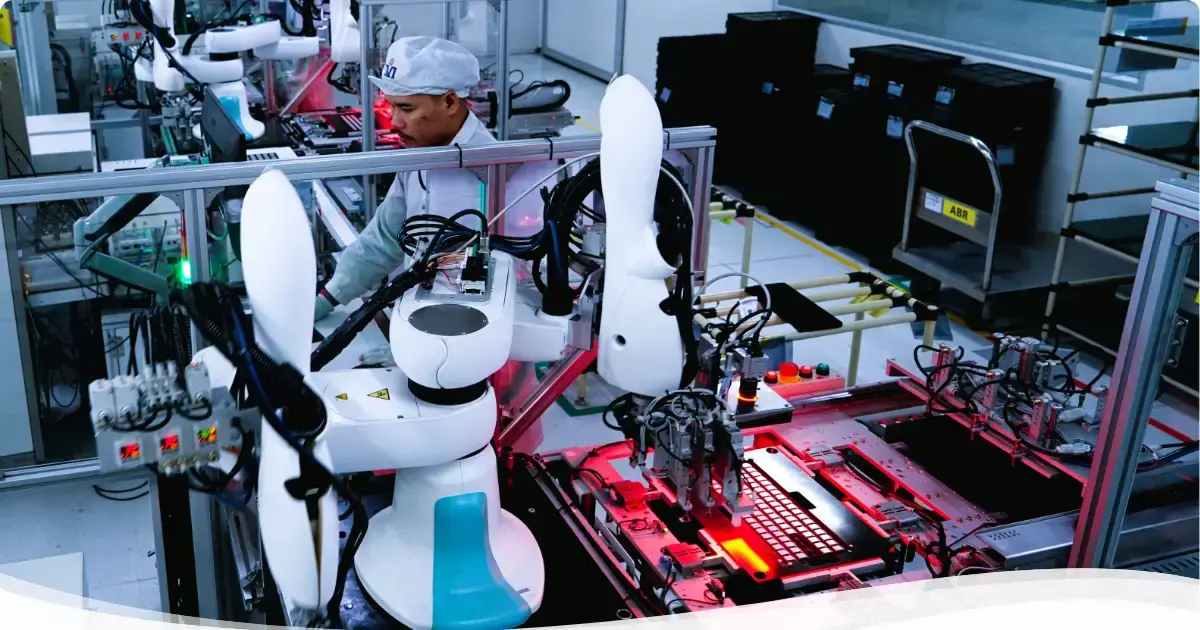

As the electronics manufacturing industry becomes increasingly competitive and market demands continue to fluctuate, the EMS provider an OEM company chooses to partner with can significantly influence its path to success. A full-spectrum EMS partner offering a full range of services brings much more than mere manufacturing capabilities. They employ a comprehensive approach that spans the entire production process, including vital internal test design and development stages. This approach ensures that products meet the highest quality and functionality standards before hitting the market.

Choosing an EMS partner equipped with comprehensive test design and development services can yield considerable advantages, such as improved product quality, accelerated time to market, cost efficiencies, and the ability to provide necessary customization to meet specific industry demands. These advantages highlight the growing trend among OEMs to partner with EMS providers capable of managing the entire production cycle, promising a smoother, quicker, and more dependable journey from product design to final delivery.

The role of test design and development in a full-spectrum EMS partner offering

Test design and development play a critical role in ensuring electronic products meet the highest standards of quality and reliability. This specialized service involves creating bespoke testing protocols and equipment tailored to each product's requirements, leveraging design for testing and functional testing standards and tools such as:

By controlling the entire production process, from initial design to development and implementation of testing procedures, EMS partners can ensure that all products undergo rigorous verification and validation processes–crucial for identifying issues early, ensuring compliance with industry standards, and guaranteeing product functionality and safety.

Integrating test design and development with other manufacturing and production services enhances the efficiency and effectiveness of the production cycle. When testing capabilities are managed in-house alongside other manufacturing steps, EMS providers can seamlessly coordinate between the different stages of product development and production. This integration allows for immediate feedback loops and rapid adjustments to the manufacturing process, which is particularly beneficial in complex industries like automotive, aerospace, and medtech.

Main benefits of EMS partner test design and development

By offering a unified, full-service approach, EMS partners can streamline production timelines, reduce costs, and improve the overall quality of the final product for OEMs, making them invaluable partners in today's technologically driven markets. Let's unpack each of these benefits further.

1. Quality control and consistency

Internal test design and development are fundamental to achieving unmatched quality control and consistency across all product lines. Maintaining testing strategies within your EMS partner's purview allows for a meticulous examination of every aspect of the product under consistent standards. This uniformity ensures that each unit produced matches the predetermined specifications without deviation.

Moreover, the ability to immediately address any discrepancies that arise during the testing phase minimizes the risk of defects and enhances the product's overall reliability. Such rigorous quality controls are especially crucial in industries where safety and performance are paramount and strictly regulated.

2. Speed to market

Integrating internal test design and development accelerates the product lifecycle, enabling a faster transition from concept to market delivery. This speed is facilitated by the close proximity of design, development, and manufacturing teams under one EMS partner umbrella, who can work simultaneously to streamline the entire process.

Quick iterations and real-time feedback between these teams reduce the time spent on revisions and ensure that the product meets all requirements before full-scale production. Consequently, this swift movement through the stages of product development not only speeds up time to market but also creates a significant competitive edge in a fast-moving industry that demands sought-after solutions be delivered as quickly as possible.

3. Cost efficiency

Incorporating test design and development within the EMS framework significantly reduces costs associated with outsourcing these critical functions. EMS partners that consolidate test development into their integrated manufacturing approach can substantially increase efficiencies for OEMs, resulting in decreased overall project costs.

Additionally, internal testing reduces the risk of costly delays and reworks by ensuring any issues are identified and addressed before reaching the later stages of production. Similarly, centralizing operations minimizes logistical expenses, eliminating the markups that come with multiple supplier contracts.

4. Customization and flexibility

Another significant advantage of using a full-service EMS partner that offers test design and development is the ability to tailor testing processes and protocols directly to a product's specific needs. This customization extends beyond mere adaptation to changes; it involves developing precise testing environments that simulate real-world usage scenarios specific to the product's intended application.

Such flexibility is critical for innovative sectors where standard testing solutions may not suffice. By being able to modify tests or develop new ones quickly, EMS partners can ensure that the product not only meets all current specifications but is also robust enough to handle future upgrades and changes, thus future-proofing the product for its lifecycle.

Strategic value in long-term EMS partnerships

Developing a long-term partnership with a full-service EMS provider that offers test design and development as part of its integrated approach brings substantial strategic advantages. Such partnerships are built on a deep understanding of the client's needs and objectives, the intricacies of the product and the specific challenges associated with its production and testing.

Over time, this relationship fosters a collaborative approach where knowledge and insights are shared, leading to continuous product improvements and innovation. This deep integration allows the EMS partner to anticipate client needs and adapt processes proactively, ensuring that the product meets current market demands and is primed for future changes.

Moreover, long-term partnerships with EMS providers support scaling efforts seamlessly. As product demand increases or market appetite changes, a trusted EMS partner with a comprehensive grasp of the product's technical and logistical requirements can scale operations efficiently and effectively to meet demand without delay. This flexibility is crucial for ensuring OEMs maintain market relevance and competitiveness.

Additionally, these partnerships enhance the ability to innovate by leveraging the EMS provider's ongoing advancements in technology and processes, which can be readily applied to the product development lifecycle. This symbiotic relationship ensures that both parties grow together, adapting and thriving as the industry evolves.

Conclusion

The advantages of partnering with an EMS provider that integrates test design and development into their overall manufacturing service offering can't be overstated. This approach ensures superior quality control, accelerates speed to market, enhances cost efficiencies, and provides the flexibility needed for customized testing solutions–benefits that collectively contribute to a robust and reliable product that stands out in the market.

By fostering a long-term relationship with an EMS partner with these capabilities, OEMs can leverage deep industry knowledge and technological advancements, ensuring their products are market-ready and future-proofed against evolving industry demands.

If you want to elevate your production capabilities and streamline your path from concept to consumer, contact SVI for more information or browse our bespoke test design and development services.

Supanee Nookaew

Supanee Nookaew

.png?width=318&height=201&name=mm-ebook%20(1).png)